On October 8, the world’s leading plastics exhibition — K 2025 International Plastics and Rubber Trade Fair — kicked off in Düsseldorf, Germany. Under the theme “Level Up! Your Advantage”, Haitian International made a grand appearance at Hall 15, Booth A57, showcasing its comprehensive “Injection Molding +” solutions. With multidimensional technological innovations, Haitian empowers customers worldwide to achieve all-round value enhancement.

On the opening day, the Haitian International booth welcomed a continuous stream of professional visitors and technical experts, engaging in lively face-to-face discussions with Haitian’s team on process details. Haitian engineers, professional and attentive, moved between machines explaining key parameters and turning technical data into service commitments, allowing visitors to experience the powerful rhythm of intelligent manufacturing in real operation.

At this year’s exhibition, Haitian International focused on four key industries — packaging, medical, automotive, and optical — presenting five intelligently designed application scenarios. Through multidimensional displays of production efficiency, flexible integration, digital intelligence, and industry expansion, the company guided visitors into a new vision of smart manufacturing.

Stepping into the booth, the two world premiere packaging models — Zhafir Zeres F all-electric packaging machine and Haitian Mars F PRO servo-hydraulic high-speed machine — immediately became the highlight of the show. With their exceptional performance, they drew crowds of visitors who witnessed the technological innovation and performance leap in the packaging industry.

The Zhafir Zeres Series medical injection molding solution for COC syringe barrels showcased full-process traceability, highlighting the cleanliness and precision demanded by the medical industry and drawing strong interest from professionals exploring collaboration opportunities. Meanwhile, the Haitian Jupiter two-platen machine’s “one-step molding” technology for automotive exterior parts also became a major highlight of the show, earning high praise from visitors for its outstanding performance in improving production efficiency and product consistency.

At the same time, Niigata’s all-electric vertical injection molding machine made its debut at the show, presenting a new solution for optical insert molding. The exhibit opened up new possibilities for high-precision molding and drew strong attention from industry professionals, who watched closely and nodded in appreciation.

In addition, high-precision CNC machines and integrated automation solutions from Haitian Precision and Haitian Smart Solutions were also showcased, presenting a comprehensive “Injection Molding +” system solution. Together, they demonstrated Haitian Machinery’s deep expertise and forward-looking innovation in the field of intelligent manufacturing.

From the outstanding performance of individual machines to the flexible integration between systems and the development of a complete industrial ecosystem, Haitian Machinery is driving a full value-chain upgrade for customers worldwide. Through cross-field synergy, systematic innovation, and turnkey solutions, the company transforms its philosophy of “Creating Value, Expanding Advantage” into tangible benefits for its global partners.

K 2025 will continue until October 15. In the days ahead, Haitian International will remain open and welcoming at Hall 15, Booth A57, greeting all industry peers committed to progress and technological advancement. We look forward to your visit — or to your continued attention to our online coverage.

No matter how you reach us, Haitian International remains dedicated to the same focus and respect — turning every injection, every set of technical parameters, and every traceable record into a lasting mark of efficiency, quality, and sustainable advancement in your factory.

The post Haitian International Debuts at K 2025 appeared first on 金宝搏手机网址.

]]>From August 1 to 2, the Haitian International Medical Industry Technology Center Open Day was successfully held in Suzhou, attracting over 200 industry experts, partners, and customer representatives. With the theme “Breaking Boundaries, Creating Value Together,” the event focused on technological innovation and collaborative applications in the field of medical injection molding. Through cutting-edge technology forums and live machine demonstrations, Haitian International showcased its high-end solutions for medical manufacturing.

At the beginning of the event, Mr. Zhu Hongguo, Director of the Medical Industry Division, delivered the opening speech. He welcomed all guests and shared insights on the technical challenges and collaboration opportunities in the medical sector.

Over the course of the two-day event, six thematic forums brought together cutting-edge topics in medical injection molding. In-depth discussions covered Haitian’s integrated PVC solutions for medical applications, the role of high-precision molds in emerging product trends, smart manufacturing solutions from Haitian Smart Solutions for the medical industry, the development outlook and market strategies in the insulin infusion sector, how RJG supports OEE improvement in medical injection molding, and how fundamental logic in polymer materials drives functional breakthroughs in medical applications. The sessions sparked active engagement and insightful questions from attendees.

At the event, Haitian International showcased eight precision injection molding solutions tailored for medical applications, covering the full spectrum of demands from micro components to large-scale devices. The demonstration area attracted a constant stream of visitors eager to observe the machines in action.

Notably, the fifth-generation Zhafir series features advanced precision molding technologies such as PDC (Precision Dosing Control), IFC (Inertial Filling Control), and OFC (Optimal Force Control). These innovations significantly enhance production stability and deliver outstanding performance in high-precision micro molding for medical applications, earning unanimous praise and recognition from attendees and industry experts alike.

Zhafir VE600V

Equipped with multi-cavity precision injection technology, this solution achieves 96-cavity molding of 0.02g PP protective caps with a cycle time under 20 seconds, meeting the demands of high-efficiency, large-scale production for miniature medical parts.

Zhafir VE900V

Utilizing micro-precision molding technology, this machine delivers stable 4-cavity production of 0.65g PBT insulin pen screw rods with a 15-second cycle time, addressing the high-precision requirements of small medical components.

Zhafir VE1200V

Powered by micro-precision molding technology, this solution completes 4-cavity molding of 2.8g PBT insulin pen plungers and barrels within an 18-second cycle, ensuring precision and efficiency.

Zhafir VE1500V

A specialized solution for medical-grade PVC, designed for 48-cavity production of 2.08g Y-type 3-way connectors used in blood transfusion sets. With a 20-second cycle time, it enhances the sealing performance of infusion systems while enabling high-throughput manufacturing.

Zhafir ZE1900V

With an 8+8 cavity design, this solution produces AS filter housings (top and bottom), each weighing just 2.5g, within a 20-second cycle—enabling precise and efficient matching for filtration devices.

Zhafir ZE2300V

Designed for high-efficiency multi-cavity molding, this system delivers 48-cavity production of 0.58g PP stop rings with a 10-second cycle time, meeting the demands of mass production for micro components.

Zhafir ZE3000V

Live on site, this machine demonstrated the molding of 32-cavity, 20ml syringe barrels using a full hot runner system with dual valve gates. Each part weighs 5.35g and is produced within a 12-second cycle, ensuring excellent precision and concentricity.

Haitian MA2100V/F

Featuring deep-cavity multi-cavity technology, this solution enables high-speed molding of 24-cavity, 1.96g PP syringe barrels in just 10 seconds, offering an optimal balance of performance and cost-efficiency.

This Open Day not only served as a platform for technical exchange within the industry, but also fostered full-spectrum engagement by seamlessly integrating expert discussions, solution showcases, and ecosystem collaboration. It highlighted the broader possibilities of medical injection molding technology.

Although the curtain has closed on the Open Day, the shared vision of “Breaking Boundaries, Creating Value” is now taking root as a new starting point for action. We look forward to seeing these solutions light up more customer production lines in the future. Driven by innovation, Haitian International will continue to join hands with its partners to push the boundaries of medical injection molding—transforming technological breakthroughs into real momentum for industry advancement.

The post Haitian Medical Technology Center Open Day Concludes with Success appeared first on 金宝搏手机网址.

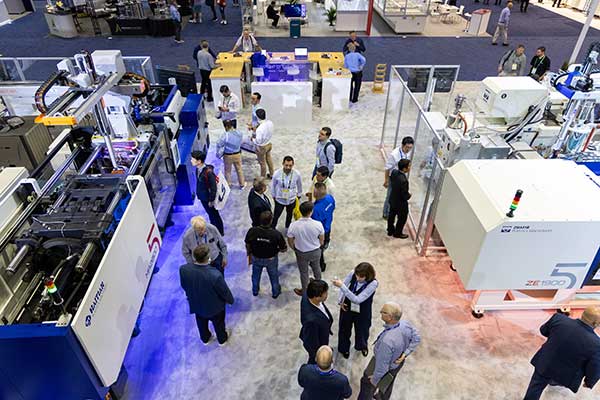

]]>On May 10th, the NPE 2024 Exhibition, held for the first time in six years, successfully concluded. As the largest plastics industry show in the Americas, it drew participants from over 110 countries and included more than 2000 exhibitors, filling over 100,000 square meters of exhibition space. The event witnessed a notable increase in professional visitors, providing an ideal platform for showcasing the latest advancements in the plastics industry and fostering meaningful discussions.

Throughout the five-day event, Haitian International made a significant impact with collective unveiling of its fifth-generation product lineup. Focusing on applications in the automotive, consumer goods, and medical sectors, Haitian International offered smart, flexible, and sustainable injection molding solutions into the global plastics industry.

Zhafir Electric Solutions

Flexible & Efficient Solutions for Medical Parts

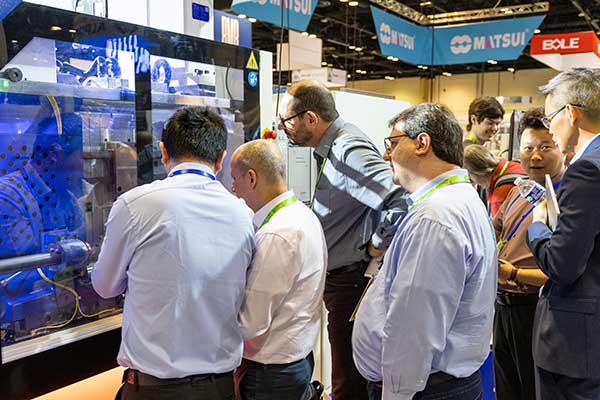

On-site, Zhafir Plastics Machinery displayed a range of specialized solutions designed to meet the diversified requirements of the medical industry.

Notably, the all-electric VE1200V-210hs with the medical package, is designed for cleanroom production standards in the medical sector. Featuring a unique medical color scheme, anti-static paint, and a suspended tie-bar design etc., it meets international standards by offering enhanced resistance to dust and oil pollution and operating with reduced noise levels.

The live demonstration featured a 4-cavity medical syringe barrel production using Tritan copolyester, with product weight of 3.2g and an impressively quick cycle time of just 18 seconds.

Additionally, the electric ZE1900V-300h machine with hydraulic integration offers a flexible and efficient alternative for the medical industry. Utilizing stack mold technology, the solution enhances productivity per area. In parallel, Zhafir’s precise control and molding technologies also support to meet with the strict dimensions and accuracy requirements for medical parts manufacturing.

The live demonstration integrates an 8×8 cavity stack mold, showcasing the medical IV filters production. The products, made from AS material, with part weight of 1.5g and 2.2g respectively, are produced with a cycle time of 18 seconds.

For both medical applications, Zhafir offers production management & information for traceability of production data and quality of medical products.

Haitian Hydraulic Solutions

Benchmark for Energy-saving, Smart and Efficient Injection Molding

金宝搏手机网址 showcased its new MA and JU series featuring fifth-generation technology, offering energy-efficient, intelligent, and high-performance solutions for the consumer goods and automotive industries. With outstanding value and performance that exceeded expectations, the new solutions received widespread acclaim and recognition in the local market.

The new Haitian MA2800V/1350 servo-hydraulic injection molding machine demonstrated the production of a single cavity consumer storage container using polypropylene, with a cycle time of 50 seconds. This innovative solution was developed after extensive upgrades to meet market demands for energy efficiency and intelligent performance in injection molding equipment. Its enhanced features cater perfectly to the consumer goods industry, providing energy-efficient and high-performance manufacturing solutions.

The Haitian JU7500V/3450 was another highlight, producing 2-cavity automotive outer panels from PC+ABS blends, with a cycle time of 60-second. This compact solution incorporates advanced energy-saving technology to significantly reduce energy consumption while achieving a dry cycle time at an internationally advanced level. By providing a high-efficiency, energy-saving, and space-efficient solution, it offers the automotive industry more opportunities for cost reduction and efficiency improvements.

Deepening Overseas Markets, Staying Close to Global Customers

NPE is the largest plastics trade show in the Americas and a highly influential event for the global plastics industry. At this year’s exhibition, Haitian International showcased not only its innovative technological advancements and cutting-edge applications, but also demonstrated its commitment to serving overseas markets with high-quality, high-value products and services.

In recent years, Haitian International has continuously increased its investment in the Americas. With the official opening of the new factory in Guadalajara, Mexico, in 2023, Haitian International established new production capabilities to serve the entire American market. Through its manufacturing center in Mexico, application experience centers in South Carolina, USA, and São Paulo, Brazil, and a comprehensive network of sales and service partners across the region, Haitian provides American customers with prompt product delivery, extensive application support, seamless service experiences, and comprehensive after-sales support.

Moving forward, Haitian will continue deepening its global market presence with practical and effective measures to genuinely connect with customers worldwide. By enhancing high-quality local production and delivery capabilities and providing efficient and convenient services, Haitian aims to be a trusted partner to global customers, exploring more possibilities for a high quality and sustainable development of the plastics processing industry.

The post NPE2024 | Haitian’s 5th-Generation Technology Goes Global appeared first on 金宝搏手机网址.

]]>On May 6th, NPE 2024, the Plastics Show, kicked off as scheduled at the Orlando Convention Center in Florida. Haitian International made a significant impact with the debut of our new fifth-generation technology at booth W943, showcasing our innovative capabilities.

Join us as we “cross oceans” to bring you live coverage from the event, diving into the day’s highlights and discussing new technologies, trends, and opportunities in the global plastics industry.

On the first day, Haitian International’s booth was bustling with activity. The first collective appearance of our new fifth-generation product matrix on the international market drew widespread attention, with many visitors stopping by to explore.

On-site, our smart, flexible, and sustainable specialized solutions attracted numerous customers and partners for enthusiastic consultations and discussions, offering new perspectives for efficient production for our international clients.

During the exhibition, Haitian International focused on consumer goods, automotive, and medical industries, presenting four core solutions—Haitian MA2800V/1350 energy-efficient consumer products industry solution, Haitian JU7500V/3450 space-saving automotive industry solution, Zhafir VE1200V-210hs clean precision medical industry solution, and Zhafir ZE1900V-300h flexible efficient medical industry solution. These innovative solutions stood out, bringing a feast of technology that’s second to none and fully powering up the “5”.

The four showcased core solutions, emphasizing energy conservation and efficiency, leverage multiple energy-saving technologies and high-precision controls to achieve energy savings of 20-40%. They also significantly reduce the machine’s footprint and cycle times, paving a new path for green manufacturing.

Moreover, the solutions extensively incorporate smart functions and hardware innovations, enriching the intelligent capabilities to digitally upgrade production processes, enhancing precision and stability in production, and enabling efficient, flexible integration across multiple systems.

These four solutions are all “Greenness + HT Xtend” showcasing the pinnacle of China’s injection molding technology, sparking an innovative wave of “technology going global”.

NPE 2024, the Plastics Show, will continue until May 10th. We look forward to your visit at booth W943 to join us at this international industry event and embark on the path of innovation with our fifth-generation technology!

The post NPE 2024 | Live from Day One: Leading the Wave of Technological Innovation appeared first on 金宝搏手机网址.

]]>